-

Email: karina@wovenbagpp.com

Email: karina@wovenbagpp.com -

Tel: 0086-13355035580

Tel: 0086-13355035580 -

WhatsApp: +86-13355035580

WhatsApp: +86-13355035580

bopp bag / wholesale rice bags

Rice bags are requested to be insect-resistant, mildew-proof and well-preserved. And to win the competition in the market, Rice bags need to be in aesthetic appearance for brand promoting. Bopp laminated pp woven bag perfectly offers the features which could meet above requests.

Capacity Size Thickness

50kg rice bag 95*55 70-75gsm

25kg rice bag 45*75 60-70gsm

20kg rice bag 45*70 60-65gsm

10kg rice bag 35*55 60-65gsm

5 kg rice bag 30*45 60-65gsm

| Bag material used | 100% virgin PP |

| Bag color | Can be white,transparent,blue,yellow etc.as per customer's requirements |

| BOPP printing | Max.10 colors |

| Bag width | 25~150cm |

| Bag length | As per customer's requirements |

| Mesh | 7*7~14*14 |

| Denier | 650D to 2000D |

| Fabric GSM | 40gsm~250gsm |

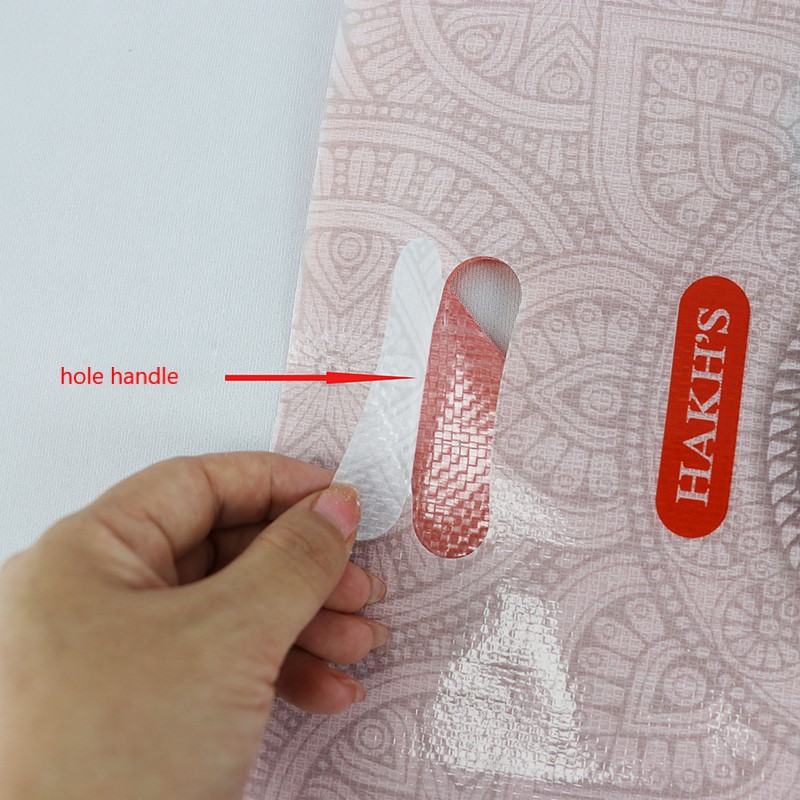

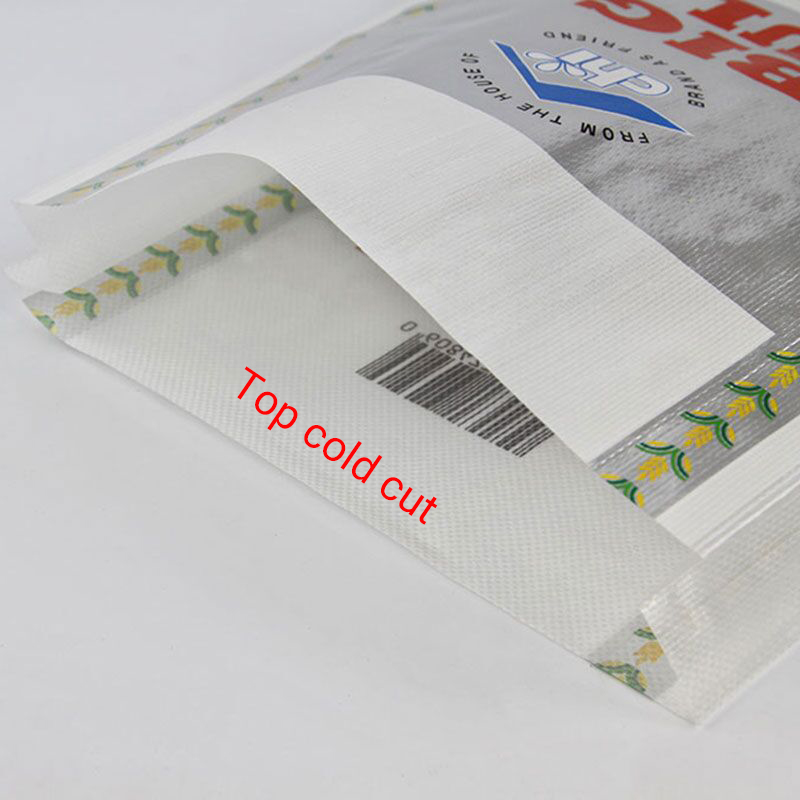

| Bag Top | Heat Cut, Cold cut,Zigzag hemmed,Hole handle cut or other types |

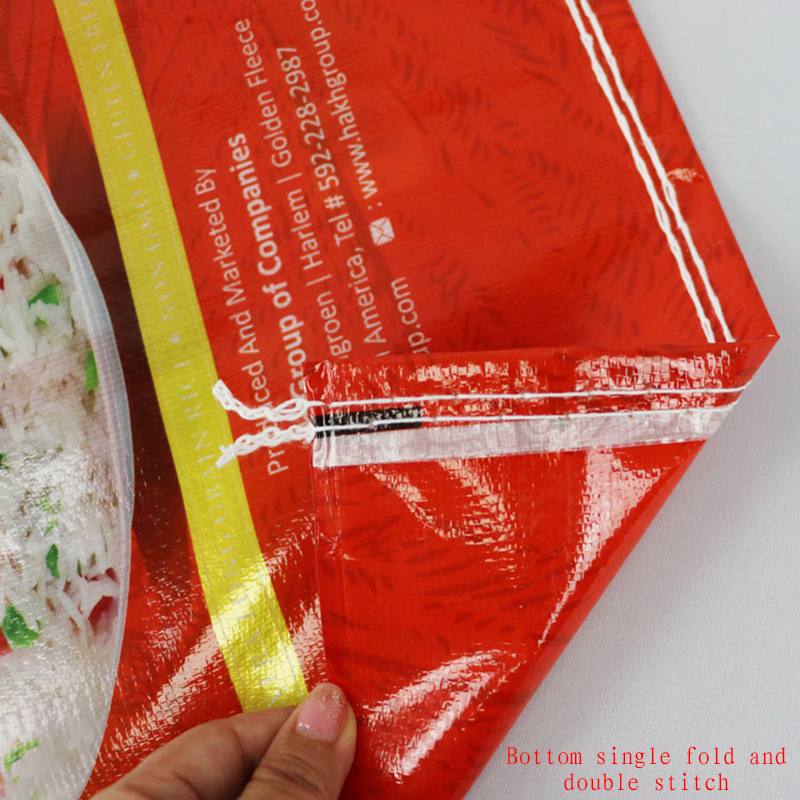

| Bag Bottom | 1) Single fold and single stitched 2) Single fold and double stitched |

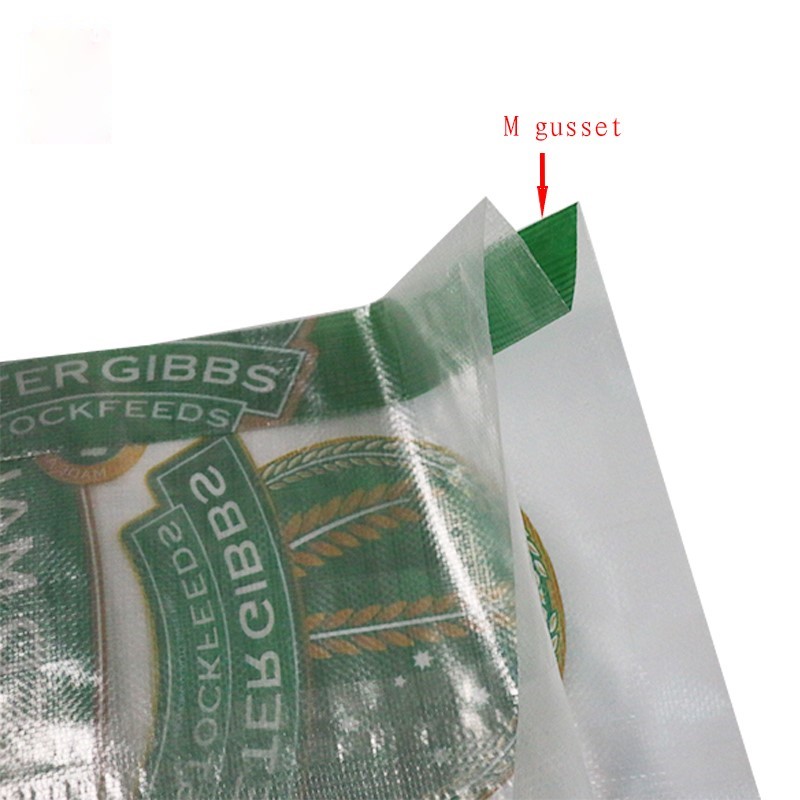

| Special Treatment for the bag fabric | 1) Can be UV treated, as per customer's requirements 2) Can be with M gusset,as per customer's requirements 3) Can be with PE liner inside, as per customer's requirements 4) Can be with micro-perforation,detailed as per customer's requirements |

| Bag Surface Dealing | 1) BOPP film printing on one side; 2) BOPP film printing on two sides; 3) No BOPP film printing,only have coating on two sides; 4) Others,as per customer's requirements. |

| Packaging | 100pcs/bundle,1000pcs/bale, or as per customers' requirements |

| MOQ | 5 tons |

| Production Capability | 200 Tons/Month |

| Delivery Time | The first container within 45 days after order confirmed,the later ones as per customer's requirements |

| Payment Terms | 1) 30% down payment by T/T before production,70% balance against copy of B/L; Western Union; L/C at sight. |

| Certification | FSSC22000,ISO22000,ISO9001,ISO14001,SGS, BV, |

| Samples | Samples are available and for free. |

| Factory | Have strong technical strength & Professional service team with more than 25 years production experience |

| Quality Control Certificates | FSSC22000,ISO22000,ISO9001,ISO14001 |

| Machines | We have 4 extrusion machines,more than 200 circular woven machines,hundreds of cutting and sewing machines,general printing and BOPP film printing machines,we also have our own PE liner producing machines and testing machines. |

| Quality and Price | We guarantee all PP bags produced by our factory is high level ones while with reasonable prices,we don’t do one-time business,what we want is long time cooperation. |